You know how it is with truck parts, right? Last Tuesday my Peterbilt 389 decided to give me grief. Dead battery right when I needed to haul a load outta here. The old box was rusted bad, like tin foil left in the rain. Gotta fix that thing. So I grabbed my tape measure, thinking I’d just run to the parts store real quick. Yeah, no. Simple got complicated real fast.

First off, didn’t even look close at the thing rusting away. Just yanked it out. Big mistake. Wasn’t just the box – the frame where it sat looked like chewed bubblegum. Probably water sittin’ in there for years. Took me two hours just cleaning that mess with a wire brush. Shoulda worn gloves – got black crud everywhere.

Alright, cleaned it up good enough. Time to measure. Pulled out my steel tape, real confident now. Measured the width inside the mounting brackets first. Noted it down: okay, 13 inches, got it. Measured side to side real quick again – no, wait, 12-7/8? Which one’s right? Measured a third time. Taped the bracket crooked the last try. It’s solid 13 inches across inside them brackets. Felt like an idiot.

Then height. Battery cable was dangling like a dead snake in the way. Pushed it aside, slid the tape down. Roughly 14 inches? Measured the depth too. Almost 17 inches deep front to back? Had to crawl under the frame sideways – stiff back didn’t help – to confirm where the back plate mounts. More rust flakes landed in my hair. Figures. Shook it out and wrote it proper: Height is 14 inches, depth is 16-3/4. Shoulda double-checked the dang manual first, but nooo, smarter than the paper it’s printed on.

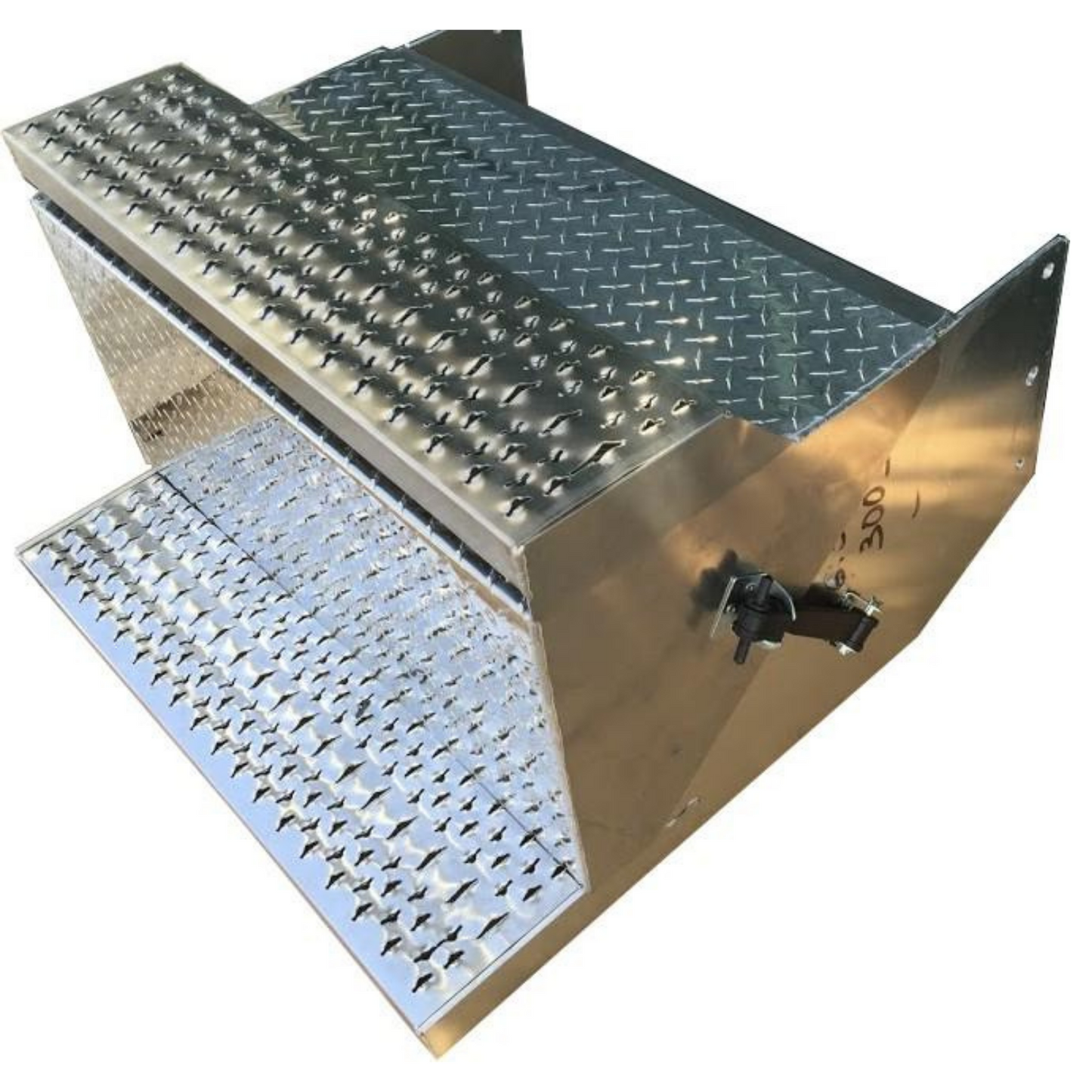

Here’s where I messed up proper: bought the box based only on those numbers. Walked into the shop, slapped my little list on the counter. “Gimme a box for a Peterbilt, 13 wide, 14 high, 17 deep.” Fella hands me a heavy steel box looking right enough.

Got home, wrestled it near the mount. Didn’t fit. Too tight – lip near the rear crossmember was catching. Cursing helped a little. Measured the opening again: needed at least half an inch clearance back there. The new box was solid steel, thicker than the paper thin rust trap it replaced. Forgot about the damn mounting hardware too – bolts needed room to stick through, but the holes sat wider than my old bracket points. Had to drill new ones by hand; metal shavings everywhere.

Finally jammed the thing in there, squeezed it past that crossmember lip. Felt like forcing a shoe two sizes too small. Bolts finally lined up mostly right. Threw some washers on it where it sat crooked. Battery dropped in snug, lid clamped down. Looks clunky but it holds.

Lesson learned? Don’t trust just three numbers.

- Width ain’t enough – measure mounting hole spacing.

- Check how much clearance ya got underneath and behind the brackets.

- Don’t forget thickness of the box walls – thicker steel changes everything.

Turns out, Pete’s got more than one way they built these over the years. If you gotta measure yours, dig deeper than I did first time. Save yourself the headache and the metal shavings down your collar. Shoulda crawled under with a flashlight and took my time looking before grabbing that tape measure.